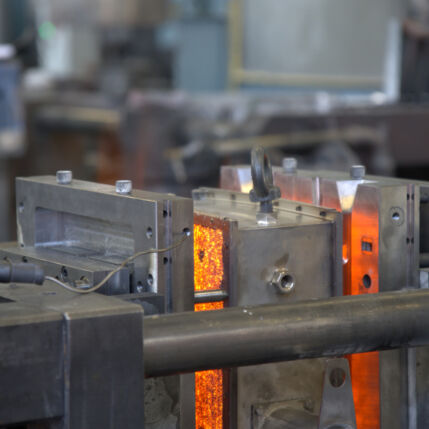

Shell moulding foundry

Mastery, Precision, and Repeatability

Gravity die casting is at the heart of our expertise.

This process allows us to manufacture aluminum parts with high dimensional accuracy, smooth surface finish, and consistent quality.

We operate several die casting machines that accommodate various mold sizes, enabling us to efficiently meet your small and medium series production requirements.

A Proven Manufacturing Process

Gravity die casting involves pouring molten aluminum into a reusable metal mold, called a “die,” using gravity. This mold is made of steel or cast iron and can be used for several hundred cycles.

Advantages of Gravity Die Casting

Excellent dimensional accuracy

Superior surface finish compared to sand casting

Cost-effective for series production over time thanks to the long lifespan of the tooling. Reusable molds = long-term cost reduction

Slower cooling → better metallurgical structure and mechanical properties

Applications

This process is particularly well-suited for manufacturing technical parts or components with complex geometries that are subject to mechanical stress:

Housings, arms, casings, safety components, urban furniture, aesthetic parts, structural parts...

Complete In-House Expertise

At Dejoie, we handle:

The design of gravity die mold plans, carried out internally by our design office. The manufacturing of these molds is then entrusted to specialized partners.

Our foundry combines industrial tradition with continuous improvement to provide our clients with robust, precise parts tailored to their specific requirements.