Foundry Casting Processes

Gravity Die Casting: A Reliable and Precise Technical Choice

At Dejoie Aluminium, we have chosen gravity die casting for the production of our aluminum parts.

This process allows us to manufacture parts with consistent quality, good surface finish, and controlled tolerances, ideal for small and medium series production.

Two Main Categories Stand Out:

Non-Permanent Molds:

The mold is destroyed to remove the part.

Advantages:

Ability to create complex part shapes

Suitable for small series and prototypes

Lower tooling cost

Disadvantages:

Limited production rate

Mold creation takes longer than casting

Low dimensional accuracy

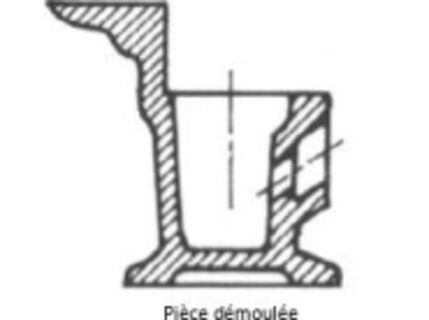

Permanent Molds

The mold, often made of metal, is reused to produce multiple series of parts.

Advantages:

High production rate

Repeatable part geometry

Long tool lifespan

Disadvantages:

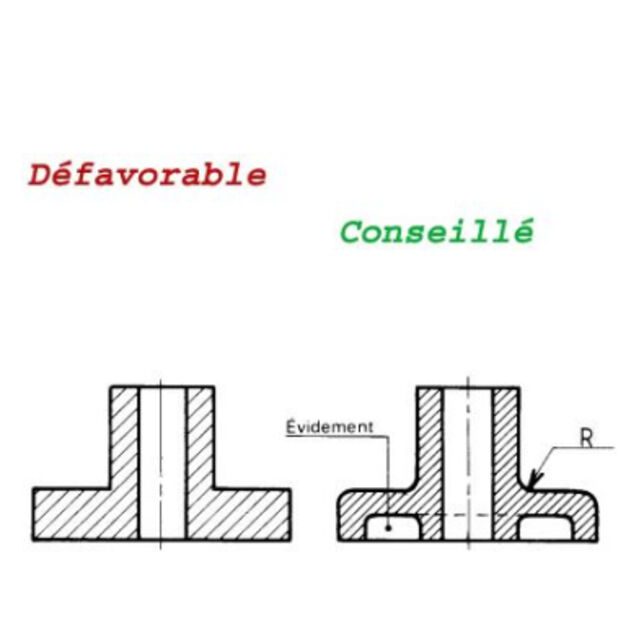

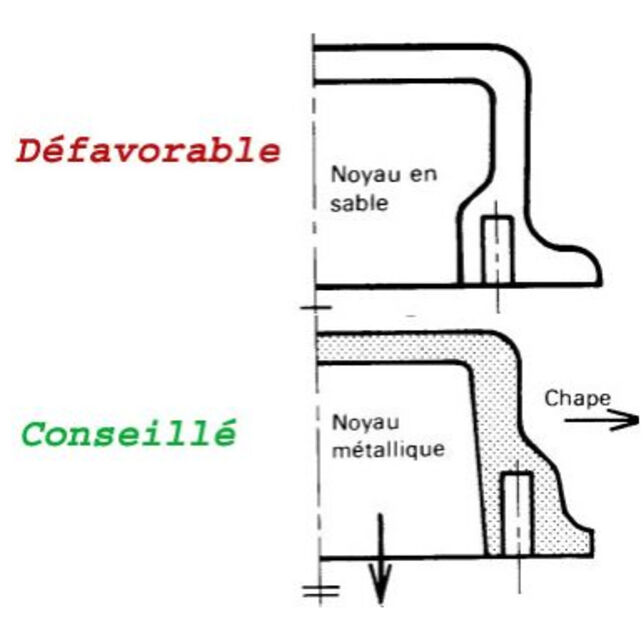

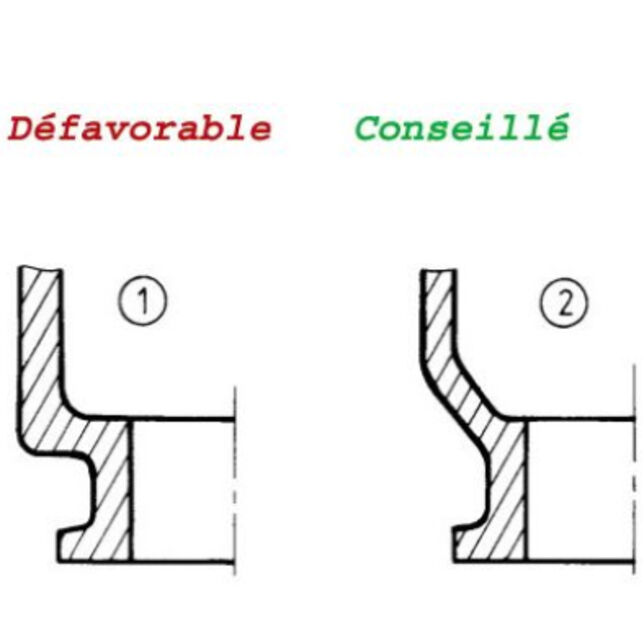

More limited shapes, as the part must be demoldable

Long-term investment

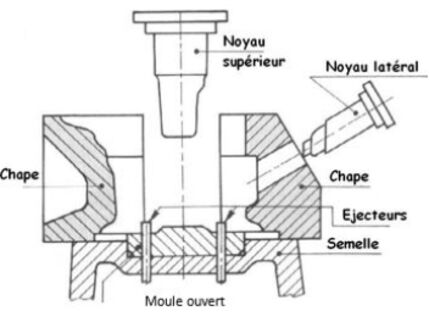

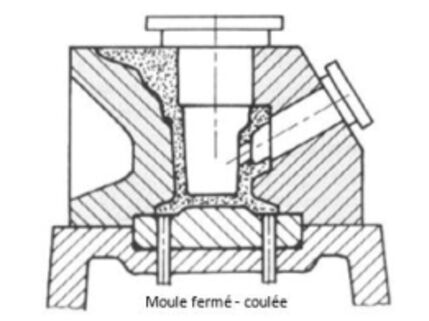

Gravity Shell Molding (Process Used at DEJOIE):

- Permanent mold, mainly made of steel

- Alloy poured manually using a ladle

- Capable of producing several thousand parts

- Good surface finish

- Good mechanical properties of the parts

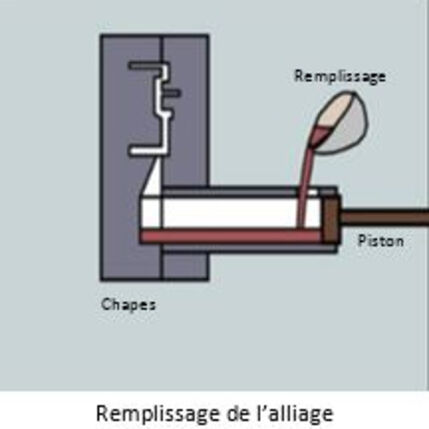

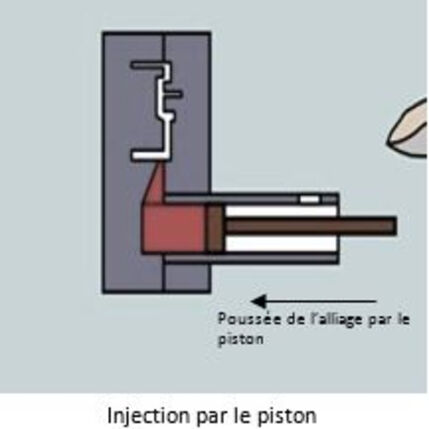

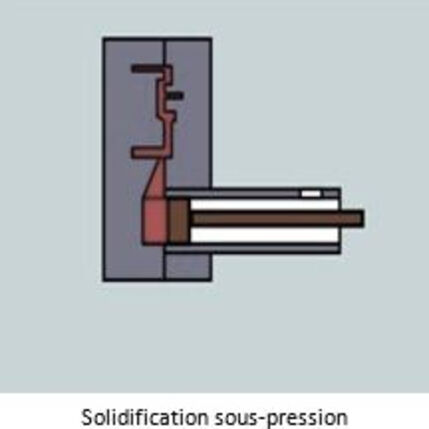

Die Casting:

Similar in principle to shell molding, except the alloy is injected into the mold using a piston or hydraulic actuator.

Technology used for large production runs

Good surface finish

Suitable for producing thin-walled parts

Sand Casting:

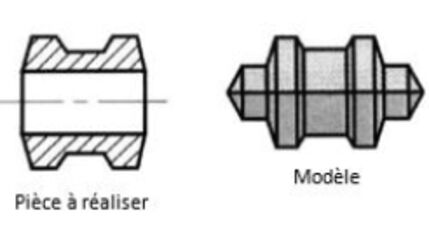

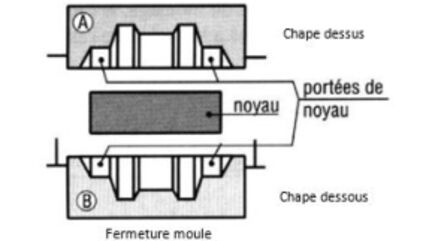

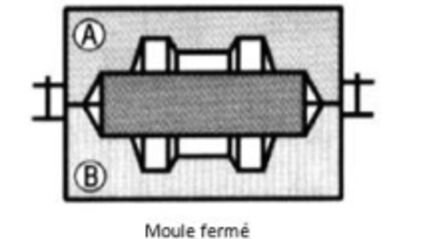

A model or pattern plate is molded in frames filled with sand, and the alloy is poured into the cavity left by the pattern.

Suitable for producing complex and large parts, including hollow sections using cores

Ideal for prototyping and small to medium series (from a few units up to several hundred)

Average surface finish and dimensional accuracy

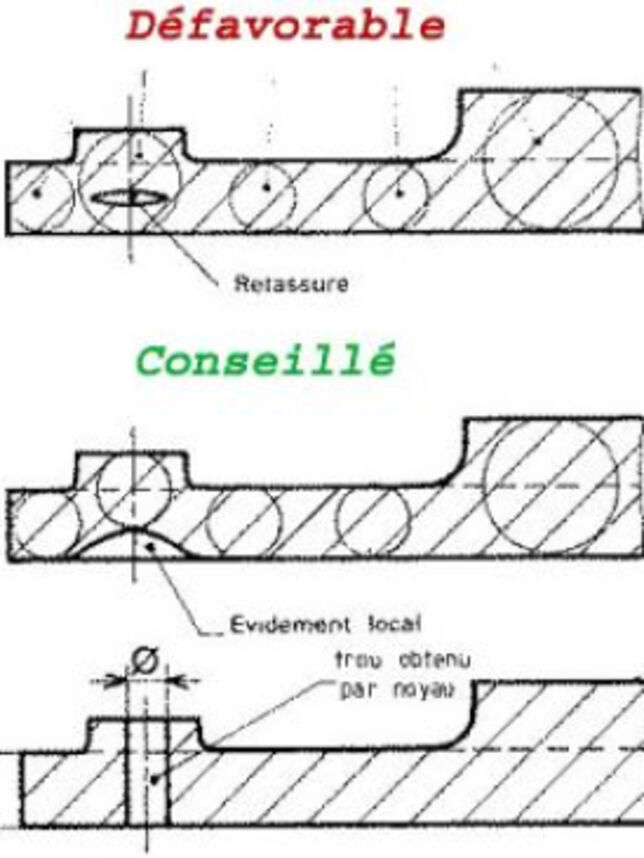

Practical Design Tips for Shell Molding:

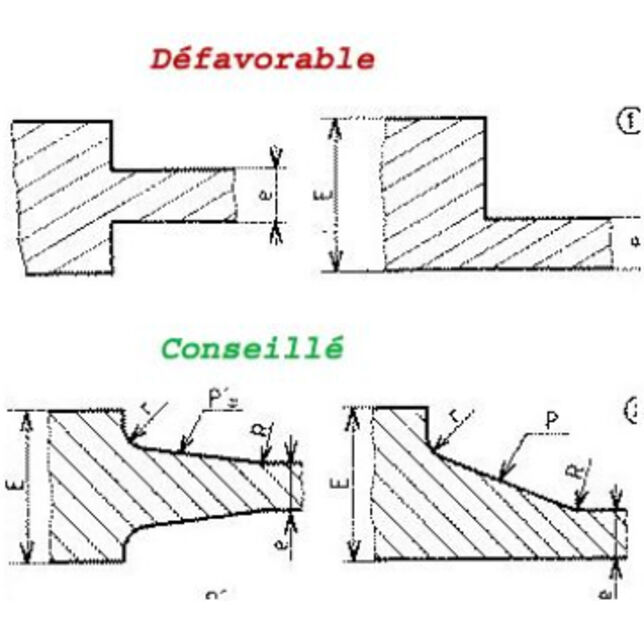

Avoid isolated masses

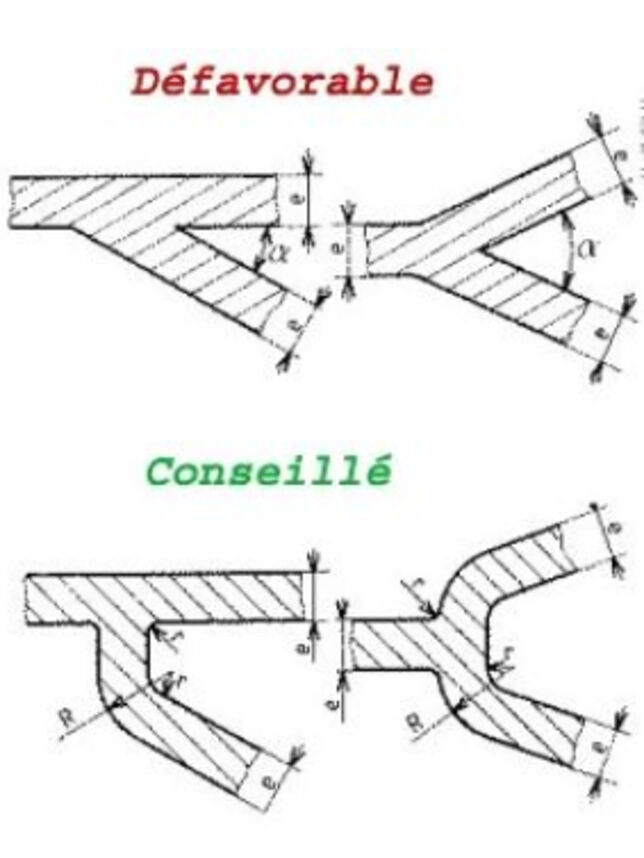

Avoid thickness variations; favor a continuous and uniform flow path

Avoid unnecessary masses